Innovative Manufacturing for Sustainable Magnets

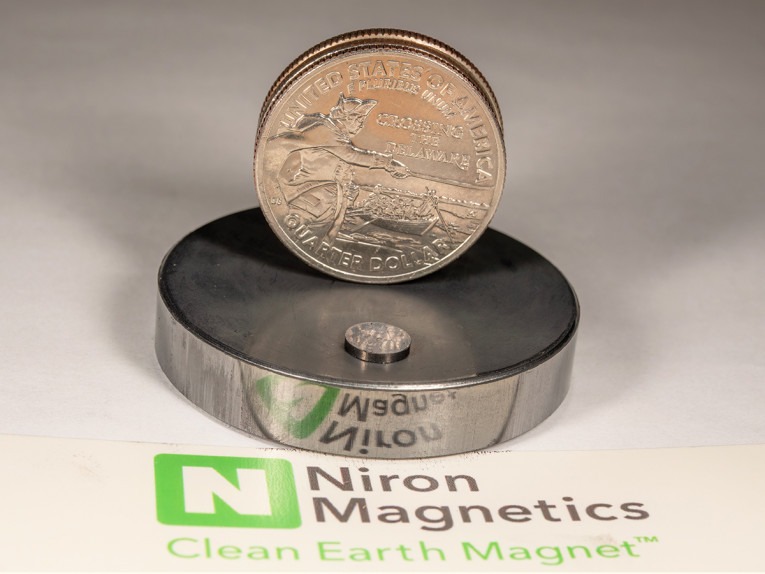

Niron Magnetics, a pioneering company in the field of magnet production, has officially opened its new commercial pilot plant in Minneapolis. This groundbreaking facility is notable for producing the world’s first rare-earth-free permanent magnets, marketed as “Clean Earth Magnets.” These magnets present a sustainable alternative to the common rare earth permanent magnets used across various industries, including electric vehicles, wind energy, and consumer electronics.

A Strategic Move to Enhance National Security and Environmental Sustainability

Currently, around 90% of powerful permanent magnets are manufactured in China, posing significant national security risks and environmental concerns due to the concentrated supply chain. In contrast, Niron’s technology utilizes iron and nitrogen—two materials abundantly available in the U.S. and sustainably sourced without necessitating new mining projects. Last year, Niron secured an additional $33 million in funding from entities such as IGM Ventures, Stellantis Ventures, and local investors including the Shakopee Mdewakanton Sioux Community and the University of Minnesota. The company is also in partnership with the Department of Defense and the US Naval Research Laboratory, underscoring its commitment to securing a domestic supply of these crucial materials.

Future Prospects and Expansion Plans

The new 70,000-square-foot facility in Minneapolis marks a significant milestone for Niron Magnetics in its journey towards scaled production. The plant boasts the capacity to produce over 5 tons of Clean Earth Magnets annually, with established processes that will be scaled to larger facilities. CEO Jonathan Rowntree emphasized the plant’s role in enhancing U.S. national security and propelling the next generation of clean energy technologies and sustainable manufacturing. Additionally, Niron has announced plans to establish a second manufacturing site in Sartell, Minnesota, with construction expected to commence early next year and production slated to begin in 2026.