Significant Expansion in Manufacturing Operations

Form Energy, a U.S.-based leader in long-duration energy storage, has announced a major advancement in its operations with the close of a $405 million Series F financing round. This investment propels the total funds raised to over $1.2 billion, confirming its status as one of the most well-funded entities in the sector. The company plans to use the influx of capital to scale up production of its pioneering 100-hour iron-air battery system across the United States.

The funding round attracted a mix of new and returning investors, including T. Rowe Price and GE Vernova, alongside Bill Gates’ Breakthrough Energy Ventures and several other prominent venture groups. In tandem with the funding, Form Energy and GE Vernova have entered into a Memorandum of Understanding to explore strategic collaborations that enhance Form Energy’s manufacturing capabilities and market deployment.

Advancements in Sustainable Battery Technology

After seven years of rigorous research, development, and pilot production, Form Energy is set to begin high-volume production of its iron-air batteries. “Our 100-hour iron-air battery system is ready for serial production and commercial deployment,” stated CEO and co-founder Mateo Jaramillo. He further highlighted the funding’s role in accelerating the establishment of new manufacturing sites, job creation, and the development of a scalable process for producing low-cost green iron.

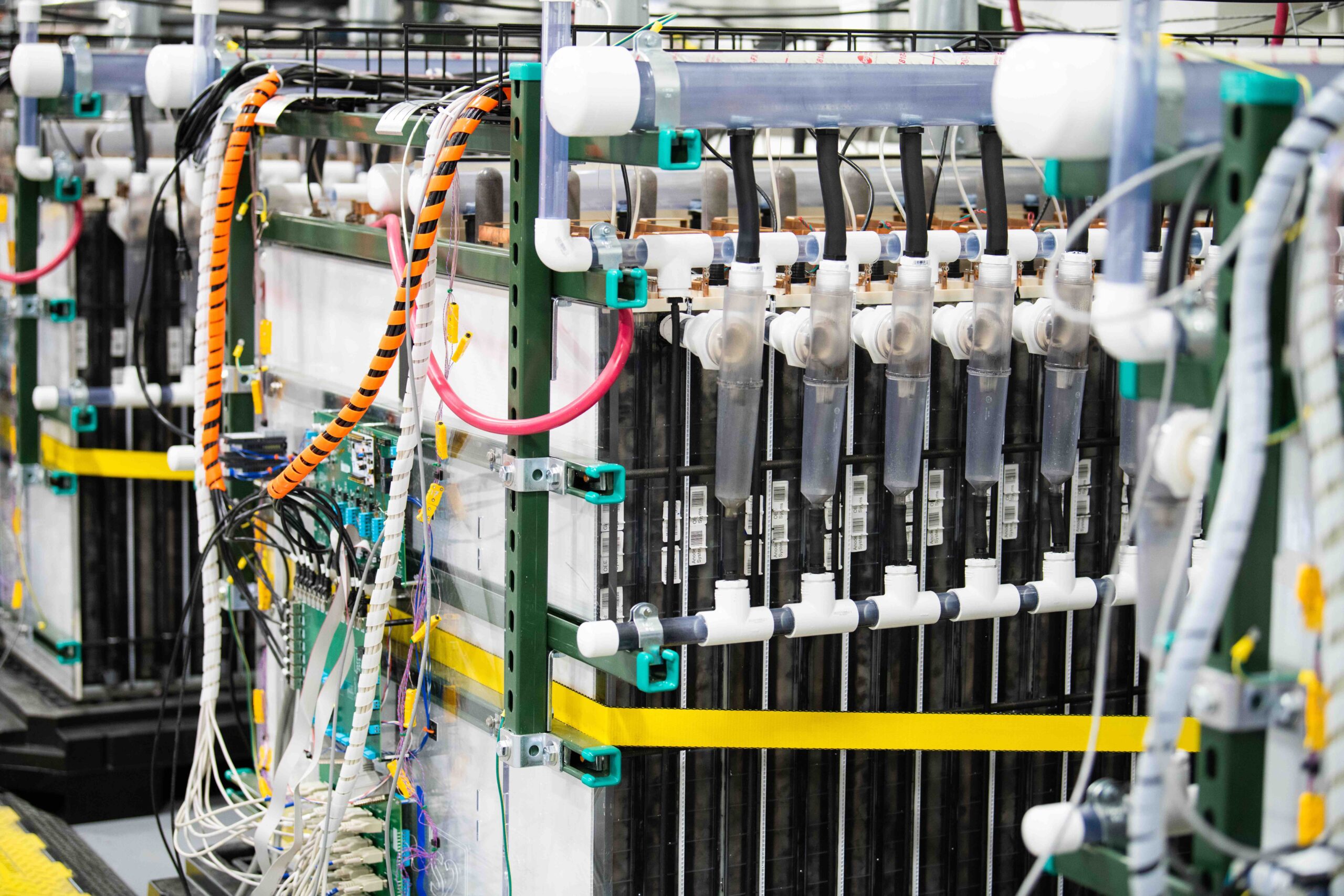

Form Energy recently inaugurated Form Factory 1, a state-of-the-art manufacturing facility in Weirton, West Virginia. This facility, constructed on the site of a former steel plant, spans 550,000 square feet and has recently commenced trial production. With plans to expand the facility to over 1 million square feet and employ at least 750 people by 2028, Form Factory 1 aims to have a minimum annual manufacturing capacity of 500 MW.

Innovative Approach to Energy Storage

The company’s battery technology is based on a novel concept of reversible rusting, using abundant materials like iron, water, and air. The technology operates by converting iron to rust as it discharges and restoring it to iron upon recharging. This system offers inherent safety advantages, including non-toxic electrodes and a non-flammable water-based electrolyte, minimizing the risk of thermal runaway.

Despite the technology being in its early stages of large-scale application, demand for Form Energy’s innovative solutions is robust. The company is developing several large projects, including what is set to be the world’s largest battery storage capacity in Maine, as well as projects in Georgia, Minnesota, and potentially Ireland.

Form Energy is also moving forward with its first commercial project in Cambridge, Minnesota, marking a significant milestone in its operational expansion and the broader application of its iron-air battery technology.