Pioneering Robotics for Precision and Safety

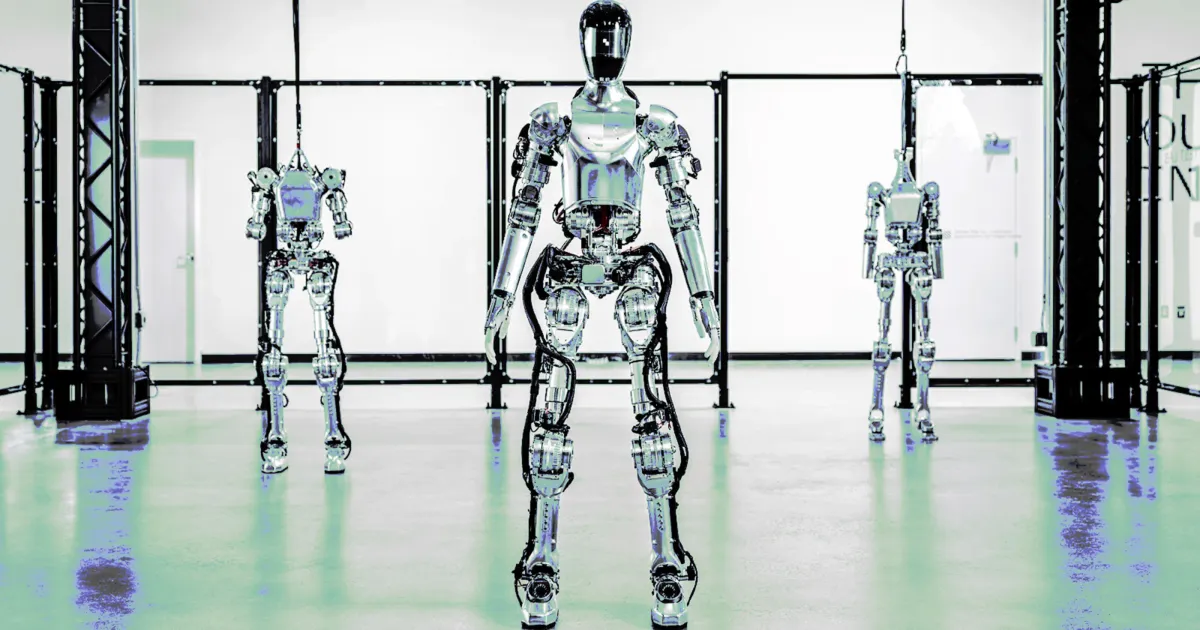

BMW has taken a significant step forward in automotive manufacturing by testing advanced humanoid robots at its Spartanburg, South Carolina plant. Over several weeks, the automaker successfully integrated the Figure 02 robot into the body shop, where it handled sheet metal parts with remarkable precision under real production conditions.

Revolutionizing Car Manufacturing with Human-Like Robots

Milan Nedeljković, BMW’s production director, highlighted the promising potential of robotics in manufacturing. “This early test phase is essential for identifying how humanoid robots can enhance our production capabilities,” he stated. The robot’s tactile proficiency is particularly valuable for intricate tasks that require millimeter-level accuracy.

Future Developments in Humanoid Robotics

The Figure 02 robot, designed with human-sized hands and the ability to walk, is engineered for physically demanding or hazardous tasks. BMW, in collaboration with California-based Figure, plans to continue refining the robot for broader applications, aiming to revolutionize automotive production with this cutting-edge technology.